Shoujia Group was established in 2002 and has been struggling in the automotive market for more than 20 years. We have taken advantage of the booming development of China's automotive industry and grown from a company located in Shiyan City to a large team consisting of many large factories scattered throughout the country. Nowadays, we have over 600 acres of Shoujia Industrial Park, supplying more than 1000 types of products to major domestic vehicle and component manufacturers, with an annual output value of over 500 million yuan.

As a component manufacturing enterprise that accompanies the growth of China's automotive industry, we adhere to the concept of "customer first, quality first, technological leadership, and win-win cooperation". This is not only our corporate belief, but also our pursuit. Therefore, we have gathered more than 500 elites in mechanical, automotive and other technical fields to polish products and serve customers, while continuously expanding our production base from Shiyan City to Wuhan, Tianjin, Xi'an, Baoding, Chengdu and other regions, forming a strong production capacity and expanding our business coverage.

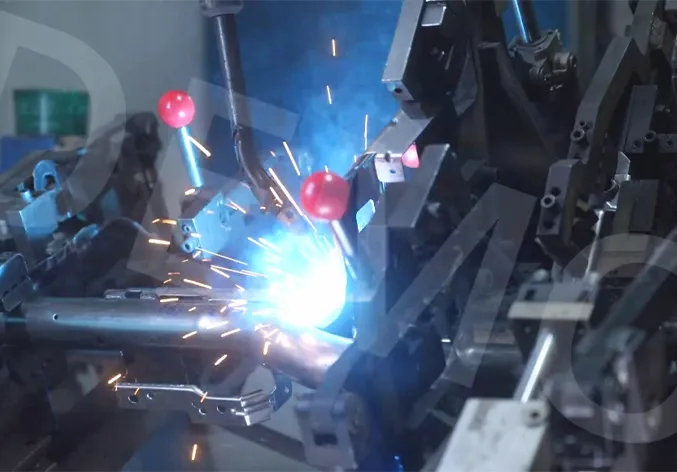

Hubei Hongyali Automotive Equipment Co., Ltd. is a high-tech enterprise focused on welding system integration, offering one-stop solutions from planning consulting to after-sales service. The company features a garden-style industrial complex, has passed multiple quality management system certifications, and has received several provincial honors.

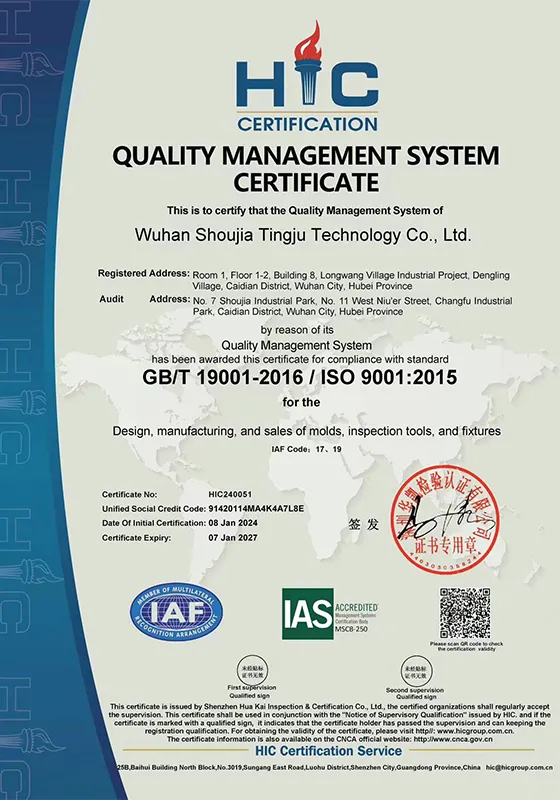

- In 2015, the company passed the ISO 9001 quality management system certification.

- In 2010, it received the "High-tech Enterprise Certificate" issued by the provincial science and technology department.

- In 2013, the company established the "Hongchuang Technology Association" to jointly cultivate more applied talents with universities.

- In 2016, it was recognized as one of the first batch of "Two-Innovation Integration Demonstration Enterprises" in Hubei Province.

- In 2018, the company jointly founded Hubei Shoujia Hongyali Automotive Equipment Co., Ltd. with Shoujia Group to enter the overseas market.

- In 2019, a 2200m² production and processing base was established.

The above information demonstrates the company’s development history and achievements since its establishment, covering aspects such as technology, project management, customer relationships, quality certifications, honors, and external cooperation.

**Business Overview**

- **Company Overview:**

- Hubei Hongyali Automotive Equipment Co., Ltd. was founded in 2003 with a registered capital of 10 million yuan. It is a high-tech enterprise focused on welding system integration.

- The company is dedicated to providing one-stop solutions and turnkey projects for automotive welding, intelligent manufacturing, and related fields, covering services such as planning consulting, research and development design, equipment manufacturing, system integration, installation and debugging, customer training, and after-sales service.

- The company’s headquarters is located in the Industrial New District of Shiyan City, Hubei Province, with a total area of 20,000 square meters, featuring a garden-style industrial complex and an intelligent manufacturing base.

- **Technical Capabilities:**

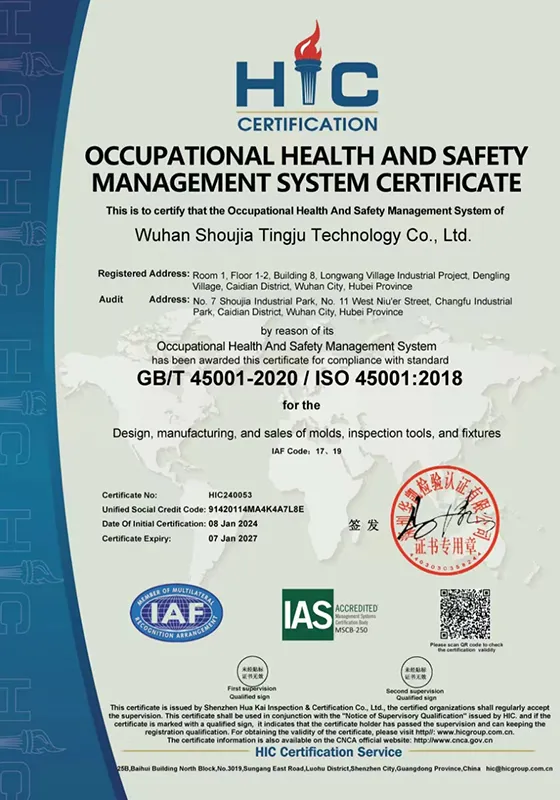

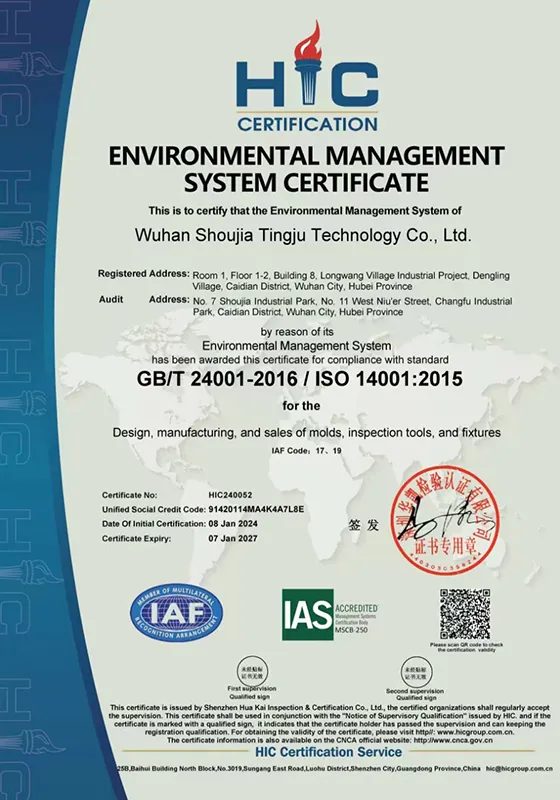

- The company holds 39 technical patents and has passed ISO 9001 quality management system certification and ISO 14001 environmental management system certification.

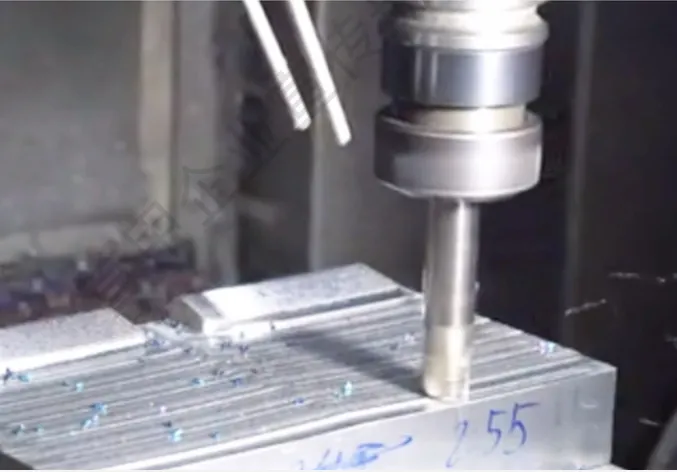

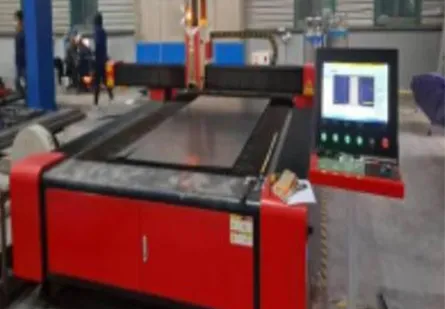

- It owns more than 40 pieces of equipment, including CNC machines, milling machines, grinding machines, drilling coordinate boring machines, machining centers, CNC gantry mills, and imported three-coordinate measuring machines.

- The company employs over 100 technical personnel, including more than 35 R&D staff and 10 senior engineers, equipped with hardware facilities such as graphic workstations and high-performance commercial computers.

- **Project Management:**

- With extensive project implementation experience and strong technical expertise, the company accurately understands customer needs and helps clients develop towards intelligent, high-end, and sustainable directions.

- The project process includes contract signing, project initiation, solution design, 3D design co-signing, design optimization, drawing release for manufacturing, processing and assembly, pre-acceptance and shipping, on-site installation and debugging, final acceptance, accompaniment during production, and warranty period.

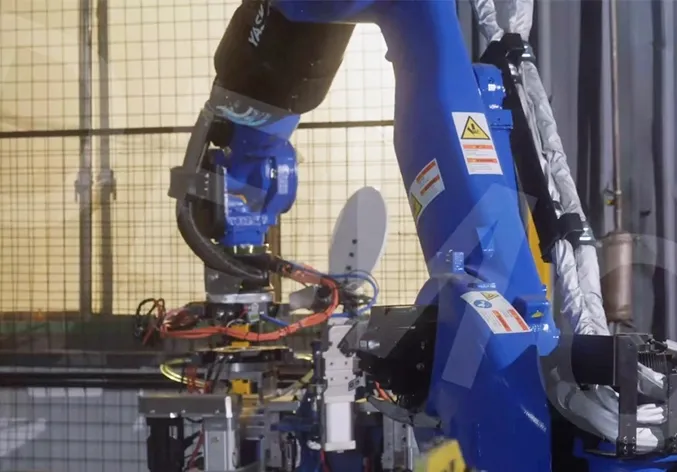

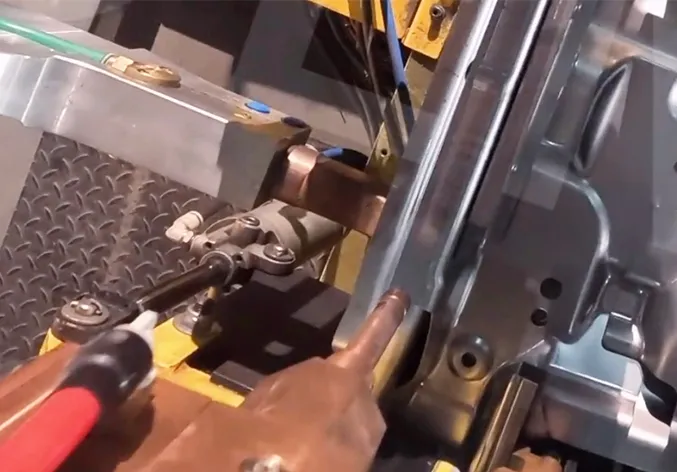

- **Project Cases:**

- The company has successfully implemented several automotive welding projects, including body welding, commercial vehicle welding, spot welding robot workstations, flange stations, arc welding robot workstations, etc.

- The projects involve well-known automotive brands such as Lotus, Yijiete, BYD, Dongfeng Liuzhou Motor, etc., demonstrating the company’s professional strength and rich experience in the automotive welding field.

**Important Matters**

- **Development History:**

- Since its founding in 2003, the company has experienced several important milestones, including establishment, renaming, obtaining the high-tech enterprise certificate, listing on the new Fourth Board of the Wuhan Equity Exchange Center, and establishing industry-university-research bases with universities.

- In 2023, the company co-founded Hubei Shoujia Hongyali Automotive Equipment Co., Ltd. with Shoujia Group to enter the overseas market.

- **Organizational Structure:**

- The company has a dedicated organizational structure, including a Party branch, technical department, project management department, etc., ensuring the efficiency of its operations and project management.

- **Major Clients:**

- The company’s main clients include LOTUS, Yijiete, and others, reflecting its strong customer base and market position in the automotive industry.

Hubei Shoujia Hong Yali Automobile Equipment Co., Ltd. is a private high-tech enterprises to provide intelligent equipment R & D and production, intelligent welding production line and other turnkey engineering services, jointly founded by Wuhan Shoujia Industrial Development Company Limited and Hubei Hong Yali Automobile Equipment Company Limited, the company's registered capital of 10 million yuan, covers an area of more than 290 acres, adhering to the “co-creative capacity, sharing Growth” development concept, bringing together the resources of the two companies, with more than 200 mechanical, automotive and other technical aspects of the talents, covering research and development, design, production, on-site installation and commissioning, after-sales service, upgrading and transformation of the ‘one-stop’ overall services, to help customers accelerate the pace of industrial transformation and upgrading We are committed to helping customers accelerate the pace of industrial transformation and upgrading by promoting the transformation from “manufacturing” to “intelligence” and “creation”.

Covering four business segments: welding equipment and flexible welding line, stamping parts and welding assembly parts series, pipe making and pipe beam assembly series and automotive sheet metal mold inspection fixture series. The company mainly serves well-known enterprises at home and abroad, such as BYD, Great Wall Motor, Geely, Dongfeng Group and SAIC Group.

In 2024, we successfully completed the JS21 welding line construction project for DEWAN in Pakistan. This project is a turnkey project, we undertake the design, manufacture, assembly, packaging, transportation, installation, customs clearance, debugging and after-sales service of the main welding line, sub-welding line; the procurement of line process equipment, including the selection of welding machine and welding pliers; the development of 64 sets of fixtures, including spreaders, 15 sets of auxiliary equipment, and more than 30 sets of outsourcing equipment.