Shoujia Group was established in 2002 and has been struggling in the automotive market for more than 20 years. We have taken advantage of the booming development of China's automotive industry and grown from a company located in Shiyan City to a large team consisting of many large factories scattered throughout the country.

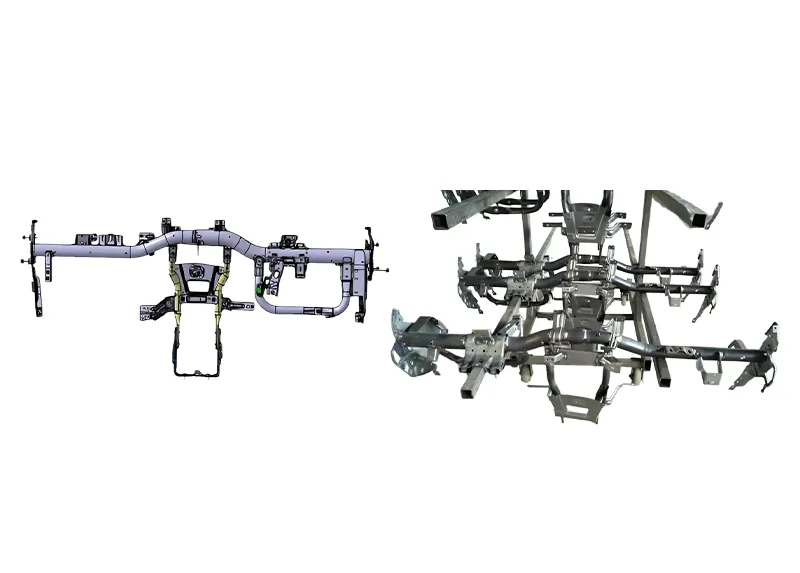

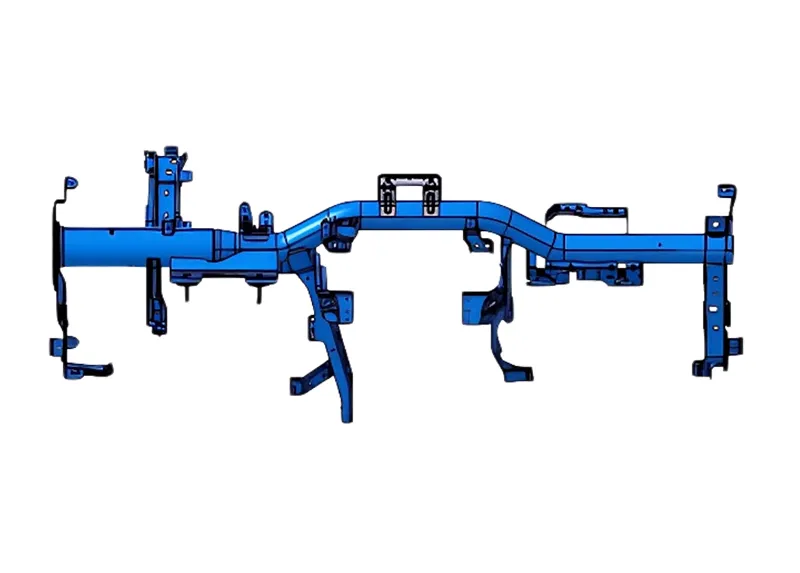

Cross Car Beam Assembly

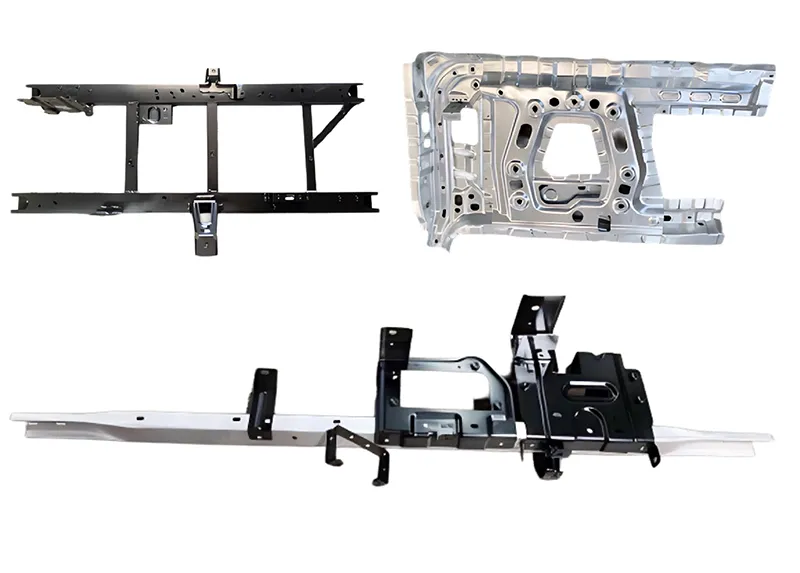

The crossmember is an intricate element that is crucial for the stability and safety of any vehicle that incorporates it. Serving as a singular cross brace within the vehicle, the crossmember guarantees that the passenger compartment remains intact during a side collision. Additionally, it provides support for the steering wheel, airbags, and the complete dashboard assembly. Depending on the specific model, this essential component can be produced using either steel or aluminum.

The crossmember is the pillar of the dashboard. From a structural point of view, the ends of the crossmember are mounted on the body wall and firewall. This means that adequate structural support for the steering column is required to ensure safety and driver comfort.

Vibration control is an important element in the design of the crossmember. If the steering column wobbles, we associate it with steering or braking problems. That is, if the crossmember is not flexing. Similarly, if the dashboard or the display in the center console vibrates, the customer will perceive the vehicle as being of poor quality. The main areas of concern for crossmembers are listed below:

Driver's side main beam

Steering column support knee pads

Steering Lift Beam

Instrument panel structure

Airbag support glove box