Custom Metal Stamping Service

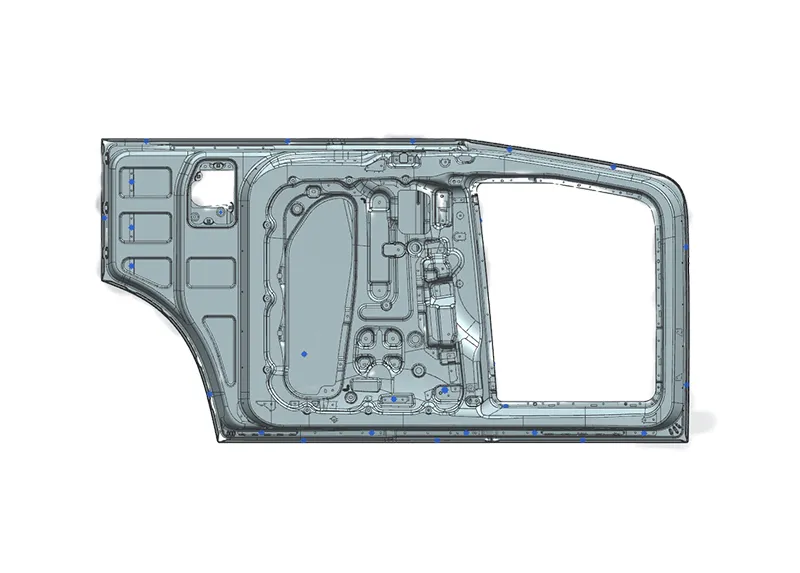

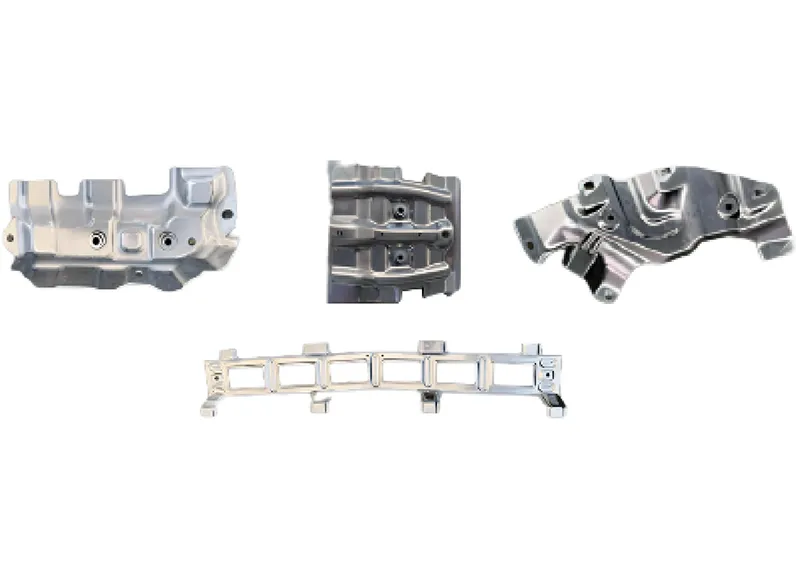

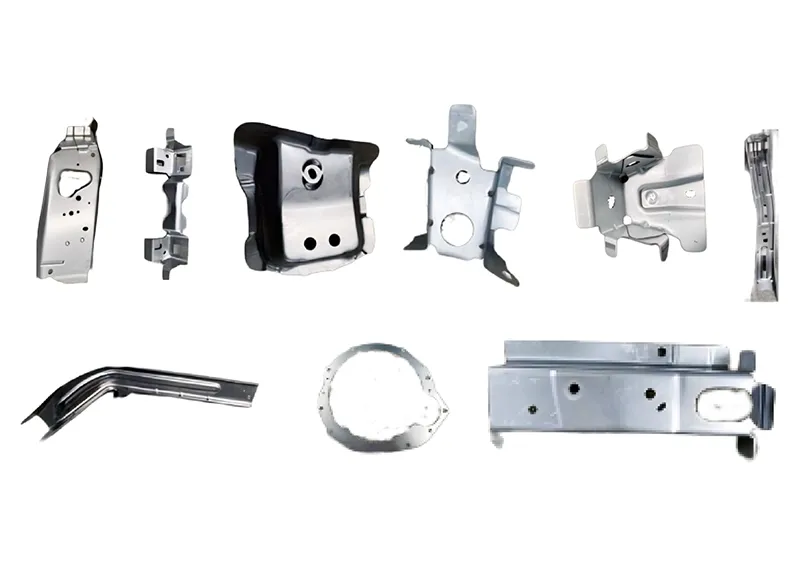

Metal stamping is a manufacturing technique that transforms coil or flat materials into designated shapes. This process includes various molding methods, including drop feed, punching, embossing, and progressive die stamping. The choice of technique may depend on the complexity of the component, allowing for the use of a combination of methods or individual techniques. Metal stamping is highly effective for the mass production of diverse and intricate parts, ranging from automotive door panels and gears to small electronic components utilized in cell phones and computers.

Automotive stamping services can be achieved through molds and mechanical equipment, usually involving a series of processes, including shearing, bending, pressing, etc.

This technology can be mass-produced in an efficient and precise manner, thereby reducing production costs and improving production efficiency.

Shoujia Group is a leading provider of custom automotive stampings service, proudly supporting the rapid growth of China's automotive industry for over two decades.With a dedicated team of more than 500 technical experts, we offer high-quality automotive stamping services that cater to the needs of major automotive manufacturers and component suppliers.

Shoujia specializes in creating custom tools tailored to your specific needs. Our engineering team is also available to provide valuable insights during the design phase, which can often lead to more cost-effective production of your automotive stampings. Additionally, we offer a wide range of secondary services such as coating, heat treatment, and plating, which can further enhance the profitability of your final product. We also provide short-run manufacturing, prototyping, specialized packaging, and assembly services for various automotive stampings.

By assisting with the design and evaluation of automotive stampings, including concept development, material selection, techniques, and manufacturing budgets, we help you achieve the highest quality and most efficient production levels in the industry. For upgrade and redesign projects, Shoujia can support the improvement of existing products and enhance manufacturing efficiency and costs through innovative stamping techniques.

Metal Stamping Processes

Custom metal stamping typically relies on high-hardness tool steel dies that are capable of cutting or shaping most metals while maintaining the tight tolerances required for your parts. Depending on your desired outcome, various metal stamping techniques can be employed. The most suitable process may involve one or more of the following:

Blanking

Blanking removes a piece (called a blank) from the original metal sheet to create a workpiece of the desired shape. It is essentially the opposite of punching, as the removed piece becomes the final part.

Punching

Punching uses a die and punch to cut the sheet metal into the required shape. The excess material is removed, and the remaining portion forms the finished part.

Bending

This process bends sheet metal to meet shape specifications. The most common forms are L-shapes, U-shapes, or V-shapes, created by bending the material around a single axis.

Deep Drawing

Deep drawing involves applying compressive force to draw the metal sheet into a cavity or mold, shaping it into the required form. This technique is sometimes referred to as forming.

Embossing

Embossing uses a die to press patterns, textures, or designs into the metal surface, adding decorative or functional features to the part.

Our Custom Automotive Stamping Process

Consultation & Design

We start by understanding your specific needs, whether it’s a one-off prototype or a high-volume production run. Our engineers collaborate with your team to optimize the design for manufacturability, ensuring that the final product meets all technical and functional requirements.Prototyping & Testing

Before mass production begins, we offer prototyping and testing services to ensure the design performs as expected. Our advanced testing facilities allow us to simulate real-world conditions, so you can be confident in the performance and durability of the product.Precision Stamping & Fabrication

Once the design is finalized, our high-speed stamping machines and advanced tooling techniques are used to fabricate parts with exact precision. We can handle a wide range of materials, including steel, aluminum, and copper, ensuring that your parts meet the necessary specifications.Post-Production Quality Checks

After stamping, each product undergoes rigorous inspection to ensure it meets all quality standards. Our quality control team uses advanced testing methods to verify that each part is free of defects and ready for delivery.Timely Delivery

Our strategic locations and robust logistics system ensure that we can deliver your custom metal stamped parts on time, even for large-volume orders. Whether you are located domestically or internationally, we ensure timely and cost-effective delivery.

Why Choose Shoujia for Your Custom Metal Stamping Needs?

Decades of Expertise

For over 20 years, Shoujia Group has been at the forefront of the automotive industry. Our deep-rooted experience in custom metal stamping allows us to understand your unique requirements and deliver precise, high-performance components for a variety of automotive applications.Comprehensive Product Range

Our diverse product offerings span 6 major categories:With an annual production of 80 million stamping parts and over 6000 tons of pipe fittings and 200,000 pipe beam assemblies, we have the capacity to meet large-scale production needs while maintaining high quality.

Stamping Series

Pipe Fitting Series

Rubber and Plastic Series

Mold Check Holder Series

Welding Assembly Series

High Temperature Tubing Series

Advanced Manufacturing Capabilities

Shoujia has a vast production network, enabling us to scale production across various regions. Our state-of-the-art facilities are equipped with cutting-edge technology, ensuring precise metal stamping, welding, and assembly services that meet stringent quality standards.Customer-Centric Approach

At Shoujia, we place our customers at the heart of everything we do. We are committed to offering a seamless service experience by providing tailored solutions to your unique needs. Whether you require prototyping, small batches, or large-scale production runs, we are ready to deliver on time and to specification.Quality Assurance

With over 20 years of experience in the automotive industry, we have refined our processes to ensure that every part we deliver meets the highest standards of quality. Our rigorous quality control processes ensure that our custom metal stamping products are durable, reliable, and perform at the highest level.Technological Leadership

We leverage the latest technological innovations in the industry to offer precision metal stamping services that enhance product functionality and reduce manufacturing costs. Our team of skilled engineers works closely with you to develop and implement the best solutions for your specific needs.Nationwide Production Base

With factories across several major cities in China, we can quickly and efficiently scale production to meet the demands of your project. This national presence allows us to offer flexibility, cost-effectiveness, and quicker lead times for large-volume orders.

Ready to Partner with Shoujia?

At Shoujia Group, we pride ourselves on being a trusted partner for major vehicle and component manufacturers across China. If you are looking for reliable, high-quality custom metal stamping services, we are here to help.

Contact us todayto discuss your requirements and see how Shoujia can help you achieve your production goals with precision, quality, and efficiency. We look forward to collaborating with you and building a long-term business relationship!