Hubei Shoujia Hong Yali Automobile Equipment Co., Ltd. is a private high-tech enterprise jointly founded by Wuhan Shoujia Industry and Hubei Hong Yali, with a registered capital of 10 million yuan, covering an area of more than 290 acres, bringing together more than 200 mechanical and automotive field of technical elites, to provide the research and development of intelligent equipment, welding line design, production commissioning, after-sales upgrades, and other full-process “one-stop” service. “We provide one-stop service. Adhering to the concept of “co-creation of capabilities, sharing growth”, we help our customers realize the leapfrog upgrade from “manufacturing” to “intelligence”.

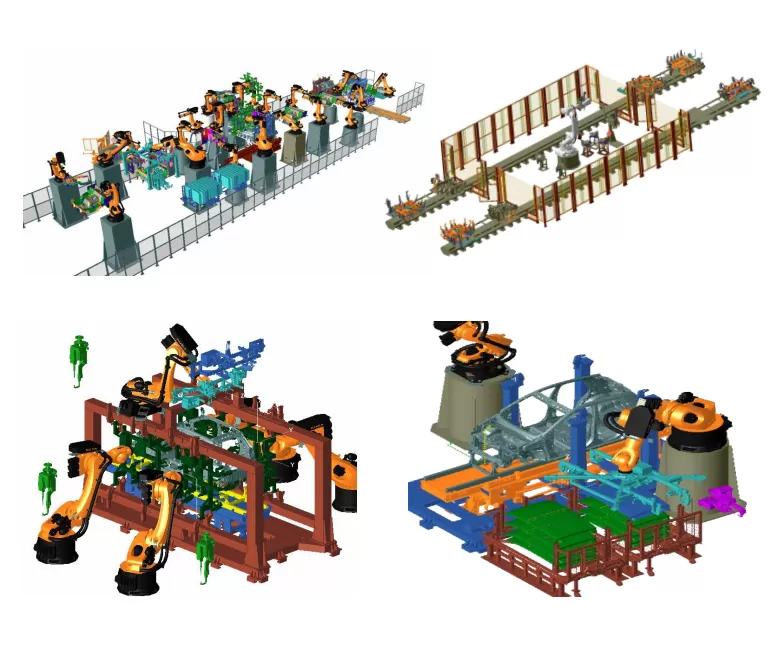

Business scope: welding equipment and flexible welding line, stamping parts and welding assembly parts series, pipe and tube beam assembly series and automotive sheet metal mold inspection fixture series. It serves the world's famous automobile enterprises such as BYD, Great Wall, Geely, Dongfeng, SAIC and so on.

In 2024, we successfully delivered the JS21 welding line project to DEWAN in Pakistan, providing “one-stop service” from design, selection, manufacturing to transportation (to China ports), installation and commissioning, and mass production support.

Client's request: Quickly build a highly compatible welding line to meet the regulations of multiple regions;

Solution: Customized flexible main welding line, self-developed 64 sets of high-precision fixtures + 30 sets of outsourcing equipment integration, support for multi-vehicle mixed-line production, and fast delivery in 6 months.

Service Process Standardization

Demand docking: In-depth research of customer demand and existing conditions;

Solution design: output fixture analysis report, layout optimization plan, equipment selection list;

Manufacturing Integration: Strictly according to the standard production, synchronized with the completion of auxiliary facilities assembly;

Installation and commissioning: stationing a team of engineers on site to ensure seamless integration;

Delivery training: provide operation manuals and on-site training to support rapid mass production.